Sharaxaada Alaabta

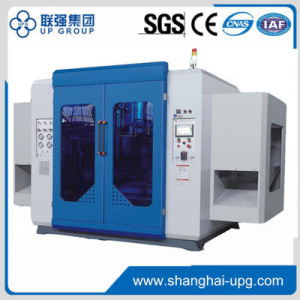

● Nidaamka balaastikada: wax ku oolnimada sare iyo caagagga isku dhafka ah, hubi in balaastiggu buuxa, lebbis.

● Nidaamka Haydarooliga: Kontoroolka saamiga laba jibaaran, dhig qaabku wuxuu qaataa tareenka toosan iyo nooca makaaniga, oo si habsami leh u socodsiiya, gudaha summada hydraulic ee caanka ah ee dibadda laga keeno. Xawaaraha qalabka, buuq yar, waara.

● Nidaamka Extrusion: doorsoomayaasha soo noqnoqda+Ilkaha dhimaya dusha sare, xawli deggan, buuq yar, waara.

● Nidaamka xakamaynta: Mashiinkani wuxuu qaataa qalabka mashiinka PLC (Shiine ama Ingiriisi) xakamaynta, hawlgalka shaashadda taabashada, wuxuu socodsiin karaa dejinta, beddelka, raadinta, la socodka, ogaanshaha cilladaha iyo hawlo kale ayaa lagu gaari karaa shaashadda taabashada. Hawlgal ku habboon.

● Dhimashada habka xiritaanka iyo furitaanka: cududda guntimaha, barta saddexaad, habka caaryada qufulka dhexe, isku dheelitirnaanta xoogga, wax qalloocan, saxnaanta sare, iska caabbinta yar, xawaaraha iyo sifada.

Tilmaamid

| Tilmaamid | SLBK-55 | SLBK-65 |

| Qalab | PE, PP, EVA, ABS, PS… | PE, PP, EVA, ABS, PS… |

| Awoodda weelka ugu badan (L) | 2 | 5 |

| Tirada dhimashada (La dajiyay) | 1,2,3,4,6 | 1,2,3,4,6 |

| Soo-saarka (wareegga qalalan) (pc/saacaddii) | 1000*2 | 950*2 |

| Cabirka Mashiinka (LxWxH) (M) | 3400*2200*2200 | 4000*2600*2200 |

| Wadarta miisaanka (Tan) | 5T | 7T |

| Unugga isku dhejinta | ||

| Xooga isku dhejinta (KN) | 40 | 65 |

| Dhiig-furanka Platen (MM) | 120-400 | 170-520 |

| Cabbirka Platen-ka(WxH) (MM) | 260*330 | 300*400 |

| Cabirka ugu badan ee caaryada (WxH) (MM) | 300*330 | 400*400 |

| Dhumucda caaryada (MM) | 125-220 | 175-250 |

| Unug soo saara | ||

| Dhexroor maroojin | 55 | 65 |

| Isku dhufashada L/D (L/D) | 25 | 25 |

| Awood dhalaalid (KG/HR) | 45 | 70 |

| Tirada aagga kululaynta | 12 | 15 |

| Korontada kululaynta hawada (aagga) | 3 | 3 |

| Awood wadista dibadda (KW) | 11 | 15 |

| Madaxa dhiman | ||

| Tirada aagga kululaynta (Aaga) | 2-5 | 2-5 |

| Awoodda kuleylinta dhinta | 6 | 6 |

| Masaafada dhexe ee laba-dhimashada (MM) | 130 | 130 |

| Masaafada dhexe ee tri-die (MM) | 80 | 80 |

| Masaafada dhexe ee tetra-die (MM) | 60 | 60 |

| Masaafada dhexe ee lix-dhiman (MM) | 60 | 60 |

| Dhexroorka ugu badan ee dhinta-pin (MM) | 150 | 260 |

| Awood | ||

| Wadista ugu badan (KW) | 18 | 26 |

| Wadarta awooda (KW) | 36 | 42 |

| Awoodda taageere ee isku xirka | 2.4 | 2.4 |

| Cadaadiska hawada (Mpa) | 0.6 | 0.6 |

| Isticmaalka hawada (m³/daqaddii) | 0.4 | 0.5 |

| Celceliska isticmaalka tamarta (KW) | 13 | 18.5 |

Video

-

LQYJBA120-220L Si Toos Ah 220L Afuufi Mouldi...

-

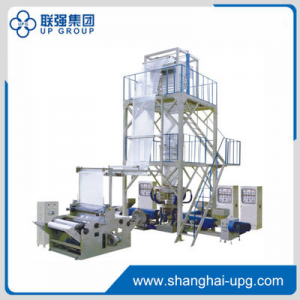

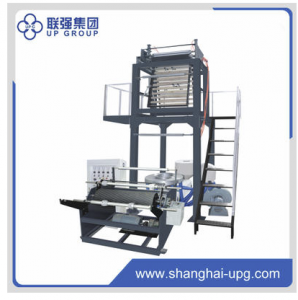

LQ A+B+C Sadexda lakab ee isku-xidhka-saarista filimka afuufaya...

-

LQ 3GS1200/1500 Saddex lakab oo Filim afuufaya Mashiinka...

-

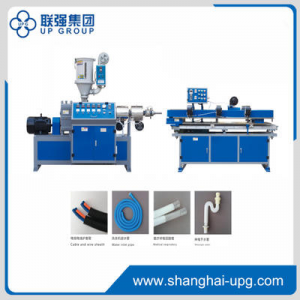

LQBUD-80&90 Soo saaraha Makiinada Wax-qabashada

-

Dhuumaha Xawaaraha Dhexdhexaadka ah ee Taxanaha LQGZ...

-

LQ Taxane Hal Lakab Filim Afuufaya Mashiinka W...